The Factory-Floor Side of Smart Digital Transformation

The Factory-Floor Side of Smart Digital Transformation

For the past decade, the manufacturing world has been shaping itself slowly but surely into another industrial revolution: Industry 4.0, a new phase that focuses heavily on interconnectivity, automation, machine learning, and real-time data.

Chen Genossar, VP at Matics, a technology company that provides real-time manufacturing analytics solutions for optimized efficiency on the production floor, shares with us his insights on the subject.

Q: What are the challenges industrial companies deal with on the production floor?

Production managers are dealing with low visibility of the production floor and constant changes in bottlenecks and sources of efficiency loss. They function in a very challenging environment and are flooded with irrelevant pieces of data that do not have the ability to transform into actionable information. Consequently, the implication to their factories’ overall productivity results in only 30% – 50% effective asset usage, high levels of material waste and machine downtime, ongoing discrepancies between standard and actual production targets, and low customer satisfaction. Moreover, managers continuously keep missing deliveries and have to deal with unnecessary quality issues.

Q: How are companies responding to Industry 4.0?

Industrial companies hear about Industry 4.0 everywhere and are swamped with information about platforms and technologies. They feel overwhelmed most of the time and do not want to be left behind, but they do not know which direction to take and what is right for their operation.

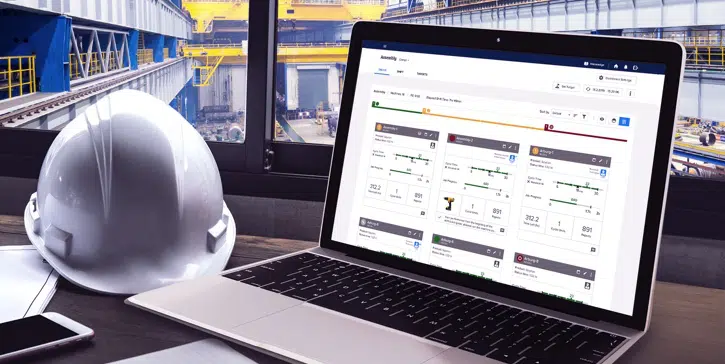

Q: What is Matics’ key value proposition for manufacturing companies?

Matics’ real-time manufacturing analytics platform is designed to help you win production efficiency. Unlike the old generation BI platforms which produce reports, dashboards, or pivot tables for post mortem analysis, Matics’ analytics

platform allows you to move past basic BI capabilities and use information and data to help focus your efforts on critical issues that demand your attention in real-time; data visualization and analysis, insights, alerts, and internal communication that help your entire team to achieve their operational goals during the shift.

Q: What are the benefits to Matics’ customers?

Besides its advanced real-time analytics tool, Matics is a secure cloud platform, which easily integrates with peripheral systems and can be deployed within hours as a low touch plug & play solution. It is designed as a suite of smart connected

applications tailored to the needs of each stakeholder, with an intuitive, user-friendly interface accessible to all the personas in your organization.

Our customers achieve on average over 25% improvement in their production

effectiveness within just a few months of operation. Matics uses innovative RtOI technologies and a machine-centric notification system that prompts immediate actions here and now, turning Matics into one of the most effective digital production tools for increasing industrial production effectiveness.

Changing the way people work in factories

Request a DemoPlast Magazine Italy