- Inability to respond quickly to production changes

- Knowledge loss, talent and skills shortage

- Lack of tools to motivate the workforce

Manufacturing Challenges

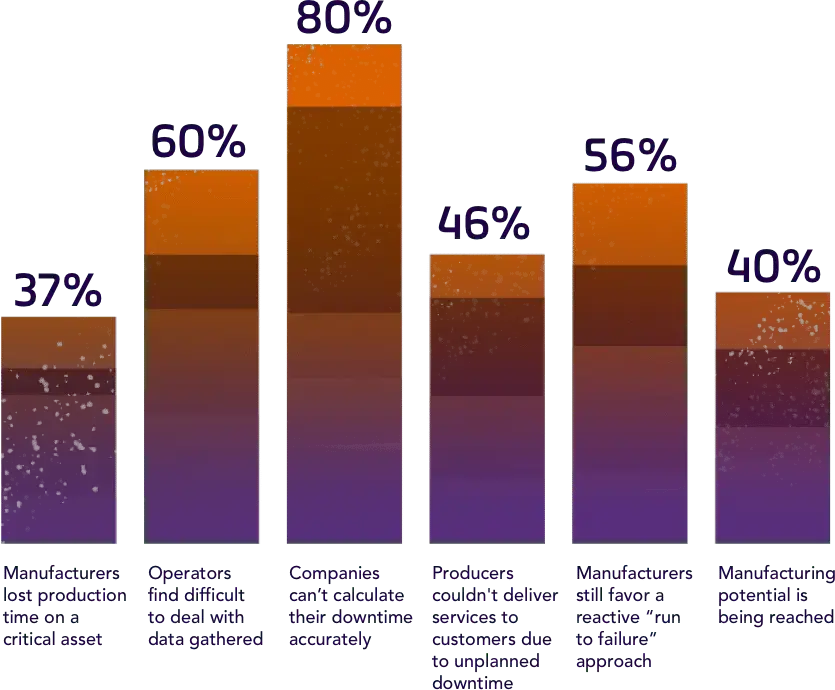

Today, manufacturers struggle with complex issues in the production environment. They contend with a skilled labor shortage and knowledge loss due to an aging workforce as well as high industry competition, and a lack of accurate shop floor data. The lack of visibility makes it difficult to react in real time to constantly changing bottlenecks. Post mortem analysis at the end of a shift is no longer enough. In addition, factory managers must also deal with rising quality demands, an inability to quickly respond to volatile market conditions, and more.

For All Stakeholders

- Burden of high upfront technology investments

- Lacking bandwidth for heavy on-prem technologies

- Security, data integrity and connectivity risks

- Data loss, inaccuracies from paper reporting

- Ineffective use of machine assets

- Unreported downtime during shift change

- Struggle to create pricing models due to inaccurate data

- Unachievable customer expectations for transparency

- No precise delivery date on which to base orders

- Huge costs for inventories, staffing & infrastructure

- Long cash-to-cash cycles

- Insufficient forecasting capability

- Difficulty maintaining the right inventory levels

- Missed delivery dates due to high rejects level

- Quality control activities out of sync or inconsistent

What are we doing about it?

Matics manufacturing analytics solution elevates your factory to a whole new level. Unlike the old generation MES systems that produce reports for post-mortem analysis, Matics collects real-time data analytics and transforms it into instant action to improve overall factory operations.

By leveraging cutting-edge industry 4.0 technology, Matics is one source of truth for everyone in the organization, instantly providing KPIs and enabling enterprise-wide communication. With straightforward actionable insights, comprehensive dashboards, and real-time alerts and notifications, Matics’ solution empowers people to make data-driven decisions and achieve 20-30% improvement in OEE in a matter of weeks.

Diverse Industries. Common Challenges.

See how Matics shop floor data analytics can help your business, no matter what industry