Matics for Technicians

React proactively and maximize resources

Maximize machine uptime and know where to prioritize resources with real-time shop floor tracking. Receive breakdown notifications and smart machine alerts for immediate communication with operators, accurate problem diagnosis and faster repairs.

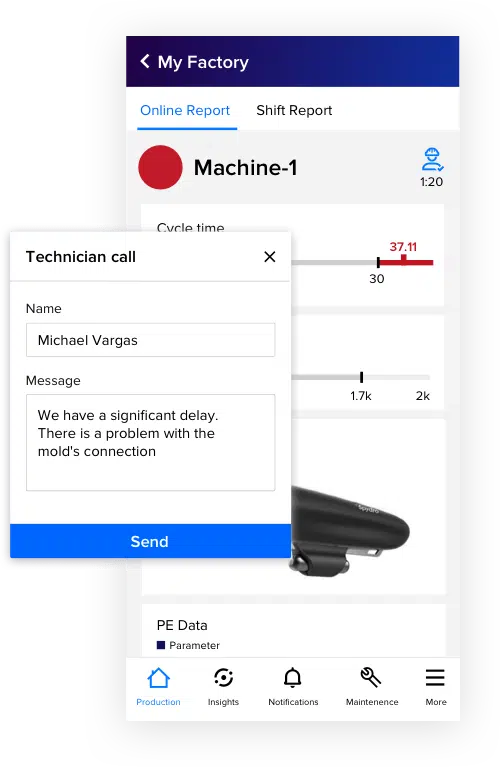

Real-time manufacturing analytics for faster fixes

View the machine’s complete production history and past communication. Access multi-parameter data and perform root cause analysis for faster problem diagnosis so you can manage the next steps.

View what happened since the beginning of the shift. Analyze stop reasons, identify the problem and communicate through the app to all relevant personnel once the fix has been completed.

Receive smart alerts and notifications when routine maintenance is due for each machine. Get breakdown notifications. Effectively prioritize resources and tasks. Track machine audits.