Matics for Quality Control Managers

Consistently ensure product quality and reduce rejects

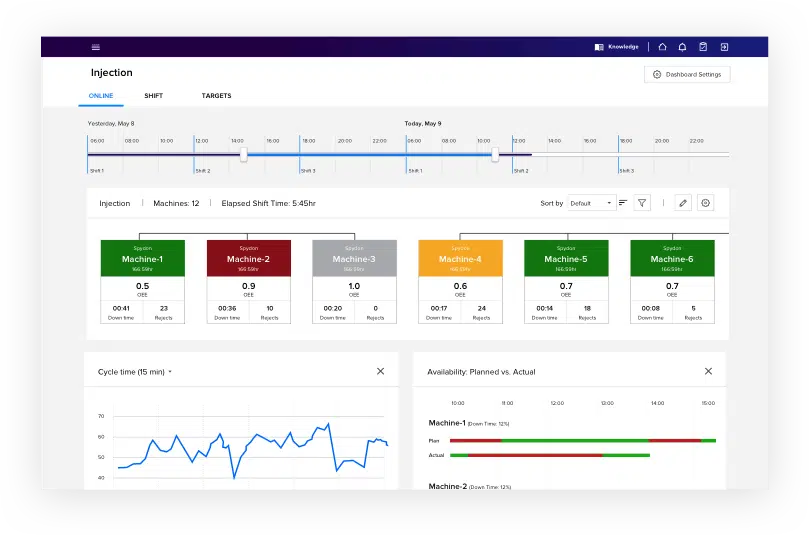

Find and eliminate sources of variability for speed and convenience via deeper levels of data analysis. Optimize processes with daily production monitoring from a central dashboard. Better anticipate delivery dates.

Unify all your quality operations with a single manufacturing analytics software, which standardizes measurements for quality plans and activities across the enterprise or units. Achieve operational savings by keeping lower inventories and generating less waste

Keep up with your quality targets using real-time OEE software which emits error-free automatic triggers and alerts based on production quantity, timing and events of all quality activities.

Define, capture and analyze test results quickly with the digitization of processes and machines. Easily design and monitor quality control procedures for manufacturing and determine their effectiveness with real-time data.