Matics for Planners

Stay on top of your production schedule

Optimize integrated planning and scheduling with a lean manufacturing tool for real-time OEE 24/7. Get real-time alerts and notifications on performance discrepancies as they happen. Track your production plan progress, proactively respond to operational slowdowns or disruptions and adjust your plan when necessary.

Data-driven decision-making for optimized results

With a real-time picture of your shop floor including real-time inventories and workflow status, you can meet any circumstance with complete confidence in your OEE planner.

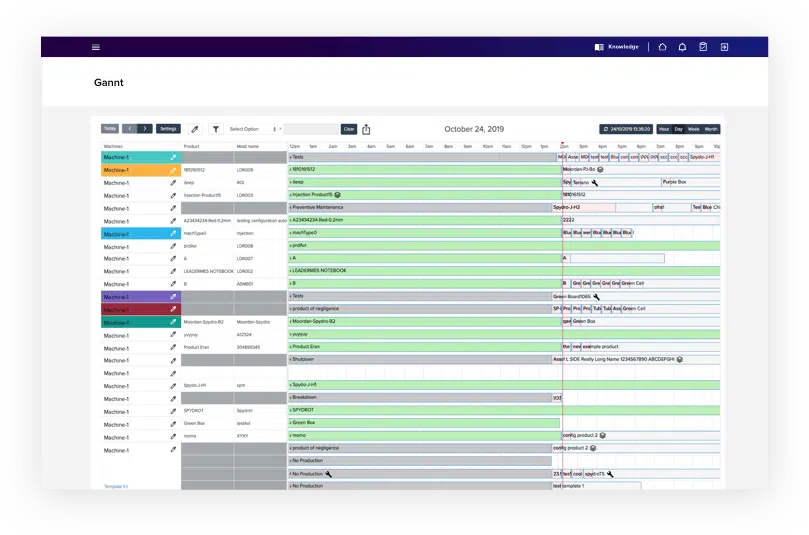

Reduce numerical errors, and make better production decisions. Monitor production rates, machine downtime, cycles and planned stops. View current activity and expected completion times for current and future jobs.

Gain a simple, reliable way to identify performance discrepancies as they happen and minimize shipment delays. Dynamically reschedule as needed. Dynamic Gantt gives you the planning tools to ensure order delivery dates.