Industry 4.0 has changed the face of manufacturing, forcing manufacturers worldwide to recognize that digitalization must take place within their shop-floor.

Today, many manufacturers have already begun transforming their shop floor and adopting industry 4.0 best practices by integrating connective technological tools. This enables them to capture all available information about their manufacturing process.

However, just capturing information is not enough.

Without the ability to filter through the digital noise, it is not possible to identify what matters most, when it matters most, and why it matters at all.

Real-time Operational Intelligence (RtOI) filters through that noise.

What is RtOI in Manufacturing?

Real-time Operational Intelligence (RtOI) is an up-and-coming industrial discipline that enables organizations to go beyond their data and gain an accurate overview of their shop-floor in real-time while providing them with the ability to effectively analyze their operations and automate tasks.

Unlike traditional software solutions that provide a snapshot view of an organization’s operations, RtOI solutions provide manufacturers with a single solution that aggregates high-resolution multi-source data, continuously analyzes it in contextual relevance, and facilitates real-time management. This enables manufacturers to shift from a reactive to a proactive approach to shop floor management.

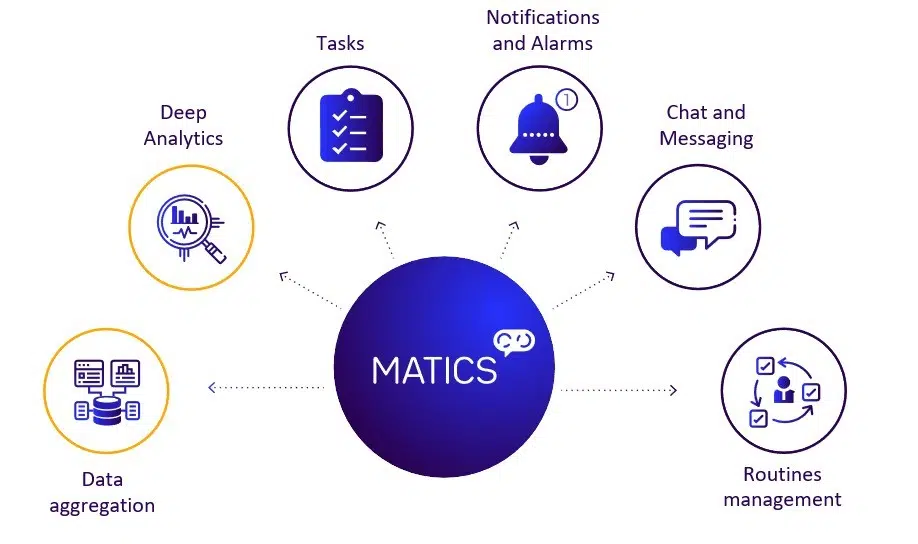

Instead of wasting time looking and waiting for information, RtOI solutions combine advanced algorithms with thousands of data points from all possible sources, including ERPs, MES, individual machines, IoT sensors, human operators, and more, enabling them to accurately identify what matters most, when it matters most, and who it matters to.

RtOI solutions then alert the right person at the right time in an application tailored to their exact needs and provide them with all the tools they need to effectively react to any shop-floor situation no matter where they are.

The result is a significant reduction in the time it takes to prevent, identify, and react to real-time events.

Key Benefits of RtOI in Manufacturing

The key advantage of integrating RtOI solutions in manufacturing plants is the ability to waste less time manually looking for and managing what technology can instantly identify and do. This enables manufacturers to reduce the time it takes for them to see, analyze and react to events, improving efficiency and productivity.

Another key benefit of RtOI solutions is the way they facilitate collaboration, improve visibility and seamlessly capture knowledge. Today, many manufacturers rely on external chat-based systems to share knowledge and communicate. These types of communication solutions are not captured by the company, easily accessible to all, or capable of providing historical and contextual relevance.

RtOI solutions, on the other hand, organize communication per job, enhancing the ability to view insight in a contextually relevant way alongside historical correspondences, improving transparency within the entire shop floor.

RtOI platforms also alert in real-time of potential outliers or shifts in performance levels. However, what managers can do once informed of a situation is the key differentiator of RtOI solutions; RtOI platforms have built-in management controls, enabling managers to react to triggers and alerts directly from their dashboard, internally communicating with relevant personal, assigning tasks, and overseeing the entire process from their dedicated dashboard. Some RtOI solutions also have a persona-based personal assistant application, making it easier for each stakeholder to see the precise information they need in the way they need it to enable them to perform their job in the best way possible.

Managers that have in-depth knowledge of their shop floor can even set automated event flows based on certain triggers or behaviors. This shortens response time, improving efficiency and production, as well as ensures that best practices are upheld no matter where they are.

In addition to providing actionable insights that enhance shop-floor visibility by analyzing real-time data, RtOI platforms can also provide predictive insights by aggregating and analyzing data and learning unique shop-floor behavioral trends within a factory or production process. This enables RtOI solutions to accurately predict the likelihood of events, such as maintenance or quality issues and alerts, before they impact operations, further enhancing operations and OEE.

Select the Right RtOI Solution

At the end of the day, manufacturers know that digitalization and integration of advanced technological tools will be the difference between failure and success.

Manufacturers that want to implement industry 4.0 best practices through integration of an RtOI solution should check to see that their selected solution offers the following:

- Non-Disruptive and seamless integration – Agile RtOI solutions can be seamlessly integrated into any shop-floor without disrupting current workflows. This includes shop-floors that have legacy machines and solutions.

- User-friendly personal assistant for every persona – The complex stakeholder network of manufacturing plants requires an RtOI solution that is easy to use and is fully customized to each person’s role and responsibilities.

- Collaboration tools with structured communication – Aggregating communication on a job basis makes it easier to understand the contextual relevance of events as well as improves transparency and visibility within the shop-floor.

- Automated task management based on pre-set triggers – Setting pre-set triggers and alerts optimizes operational efficiency, however, the ability to automate tasks based on these triggers reduces response time and optimizes operations at a larger scale.

- Continuous aggregation and analysis of multi-source data – The manufacturing shop-floor continually changes; to know the relevance of these changes, it is necessary to aggregate all possible information in real-time from any ERP, MES, and Machine.

- Scalable to any size of manufacturing plant – Multi-factory operations require a multi-language interface and the ability to optimize KPIs on a company-wide scale, single factory, single production line, and even within a single shift.

By integrating RtOI solutions that have all of these features, operation management will be streamlined with ease. This will provide managers and key stakeholders with a holistic overview of their shop-floor no matter where they are, well as improve communication and visibility for all.