Matics for Operators

360 digital support to meet your shift’s targets

Matics enables you to collect and analyze data in real time so you can obtain immediate and actionable insights during your shift — and not post mortem. With all that information stored in the cloud, you can maintain transparency and communicate effortlessly with your stakeholders.

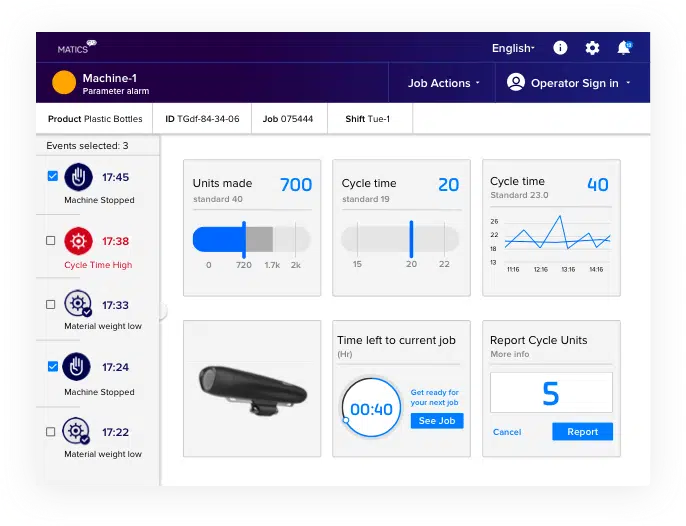

Stay on top of your production progress with 24/7 machine monitoring

Leverage a real-time dashboard to track your shift’s progress and to meet targets. Prepare and activate your next job digitally. Get automatic alerts and enter stop reasons in real time.

Connect and communicate digitally with other teams in the context of production. Send instant notifications in case of unexpected events. Call the technician and provide all relevant data in real time.

Go paperless and never again experience information loss or data discrepancies. Access any information in the blink of an eye and pass on important insights to the next shift’s team.