Best Ways to Successfully Reduce Manufacturing Giveaway

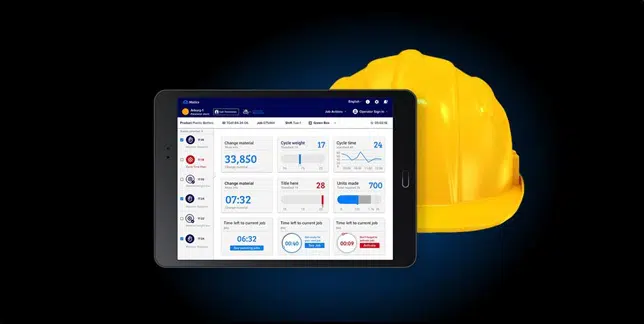

The food industry is notorious for having high levels of giveaway in its manufacturing processes despite its lower-than-average profit margins. Reducing product giveaway is therefore an easy way to increase the profitability of food manufacturing facilities without requiring extensive investments or equipment overhauls. MES software allows you to perform real-time materials management that may greatly lessen the amount of food

Last Modified: March 21, 2024