Unlocking Your Profit: How Automation Becomes a Revenue Driver

In the dynamic manufacturing landscape, automation is a beacon of progress and efficiency, driving forward the industry for years. With the advent of digitalization solutions and advanced technologies, the shift towards automated processes has become not just a trend but a necessity for manufacturers looking to improve profitability, productivity, and competitive advantage.

The transition to automation may require a substantial initial investment, from acquiring cutting-edge to equipment integration and training staff. However, this upfront cost pales compared to the long-term financial gains that automation can yield for a plant. Automated processes are less costly to integrate than equipment automation and can still lead to substantial savings in labor, maintenance, and operational costs, making them ideal for manufacturers looking to slowly digitalize their plant and automate processes in a cost-conscientious way.

Key Areas Where Automation Enhances Profitability

Labor Cost Reduction

One of the most immediate benefits of automation is reduced labor costs. Automated systems can perform the work of several people, often more efficiently and without the need for breaks or shifts. This reduction in the workforce leads to a direct decrease in payroll expenses, significantly impacting the bottom line. Automated processes reduce time wasted and leverage real-time and historical knowledge to improve efficiency when it matters most.

Efficiency and Productivity Gains

Automation brings unparalleled efficiency and productivity to manufacturing plants and processes. Machines operate faster and with greater precision than human workers, drastically reducing production times and the margin for error. This increase in productivity not only boosts output but also ensures a consistent quality of products, leading to higher customer satisfaction and repeat business. Automation of processes also significantly improves efficiency and productivity by triggering workflows, such as calling for a maintenance technician when a known error occurs or alerting when a particular material is running low and may interrupt operations.

Scalability and Market Responsiveness

The ability to scale operations quickly is crucial in today’s fast-paced market. Automation provides this flexibility, enabling manufacturers to ramp up or scale down production in response to market demands. This agility is key to maintaining a competitive edge and driving profitability in a fluctuating market.

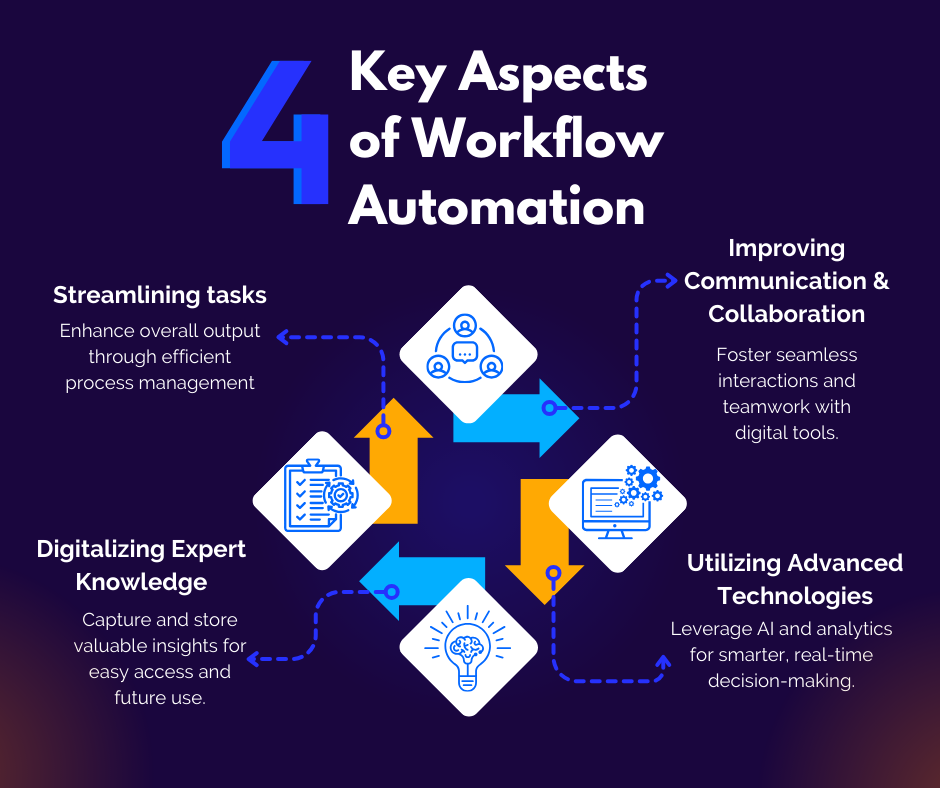

Workflow Automation and Reduced Response Times

Workflow automation streamlines processes, leading to more efficient operations and significantly reduced response times. This quick turnaround in processes ensures that manufacturers can address issues and adapt to changes in the production cycle promptly, leading to increased operational efficiency. Workflow automation leverages real-time data, historical manufacturing data, and human input to optimize processes on the manufacturing floor, reduce response time to critical events, and improve the connectivity of key stakeholders to shop-floor events.

Top of Profitability Drivers

Predictive maintenance stands out as a prime example. By leveraging real-time data, this approach anticipates and prevents critical equipment failures, minimizing downtime and extending machinery life. The cost savings from this proactive maintenance and the boosted production efficiency are significant.

Another key profitability driver enhanced by automation is Quality Control Optimization. Automated systems guarantee that each product adheres to stringent quality benchmarks. This meticulous oversight drastically cuts down the rate of defects and returns. Automated QC also ensures that real-time triggers and alerts are delivered to key stakeholders when quality thresholds are approaching. The financial benefits are two-fold: not only are costs linked to rework and waste minimized, but such consistent quality enhances a manufacturer’s reputation, enhancing customer loyalty and encouraging repeat business.

Another crucial area where automation can improve profitability is Raw Material Management. Here, automation ensures the optimized use of materials, greatly reducing waste and refining inventory management. Such precision in handling raw materials leads to noticeable cost savings, contributing to a leaner production process and the overall financial health of the manufacturing operation. Automation of raw material management also provides the benefit of digitalizing materials, knowing when materials are running low, and ensuring that material issues do not cause disruptions in production.

Lastly, Knowledge Management and Process Standardization represent another facet where automation profoundly impacts. Automation captures and codifies the expertise and decision-making processes of human experts traditionally held by skilled personnel. This digitization and standardization of knowledge ensure uniformity in production processes and diminish reliance on individual expertise. The consequence is a more reliable and streamlined operation, with considerable financial benefits from increased efficiency and reduced training needs.

Together, these elements of modern automation converge to forge a path toward greater efficiency, reliability, and profitability in the manufacturing sector.

Strategic Implications of Automation

Integrating automation with real-time data analysis tools like Matics enables manufacturers to make informed, strategic decisions. This data-driven approach allows for continuous optimization of operations, further enhancing profitability. Beyond improving existing operations, automation serves as a catalyst for innovation and exploring new markets. It enables manufacturers to experiment with new product lines and enter new markets, driving business growth and diversification.

Platforms like Matics play a crucial role in maximizing the profitability benefits of automation. By providing real-time insights into every aspect of the manufacturing process, Matics enables continuous monitoring and optimization, leading to increased efficiency and cost savings.

Changing the way people work in factories

Request a DemoThe Time to Drive Profitability Through Automation is Now

The impact of automation on profitability is clear. From reducing operational costs to enhancing product quality and enabling strategic business decisions, automation is a critical tool in the modern manufacturing landscape, especially as industry 4.0 and industry 5.0 best practices begin to be adopted by manufacturers worldwide. Book a free demo with Matics to learn more!