Are Digital Transformation and Remote Manufacturing Management Achievable During COVID-19?

The COVID-19 quarantine has forced businesses everywhere to shift to remote operations and drastically re-evaluate the scale of their operations for the immediate future. The coronavirus’ impact on manufacturing is no different. This pandemic is causing major disruptions in the usual forces of supply and demand and forcing managers to monitor production lines and resource usage at a distance; in short, business, as usual, is no longer sufficient.

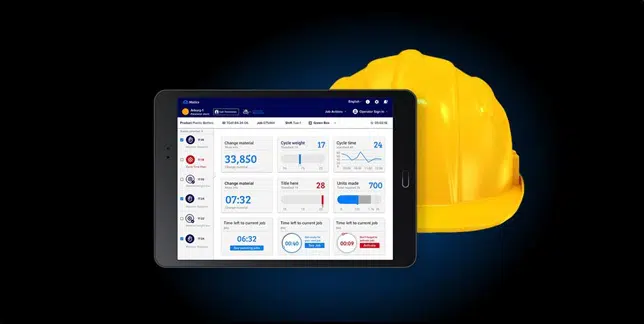

Now is an excellent time to consider digitizing your factory with the right shop floor control software. Implementing a cloud-based manufacturing execution system allows you to maintain precise control over every facet of your operations, even when you are far away. In fact, the detailed real-time shop floor analytics that such software provides will give you even greater insight into what is happening on your factory floor than you would have if you were standing right next to your machines.

Having that much information at your disposal is invaluable in times like these, and the solution is within every facility’s reach. A modern manufacturing control software is easy to install without any professional IT assistance, and it can be fully implemented and deployed at a distance. No matter how the virus is affecting your facilities, using software like this will help you adapt to this new environment and continue to flourish well after the pandemic ends.

The Two Sides of Manufacturing During Coronavirus

Nearly every manufacturing business is currently facing one of two situations.

In the first instance, production is down. You may have staffing problems due to the quarantine, or demand for your product may have all but evaporated as supply lines have been redirected to essentials, and customers’ wallets have emptied. You are probably experiencing far more downtime than you are used to and may be searching for a way to make the best out of this slow period.

On the other hand, not every business is experiencing a slump; many are seeing a surge in sales for their products, especially if they produce essentials like canned food, toilet paper, and disinfectant. In these cases, the typical production processes you were using prior to the outbreak are likely not sufficient to create the massive volume of product that you need now.

Manufacturers in either situation could benefit from installing manufacturing control software, albeit in different ways. Each scenario is covered in further detail below.

Scenario #1: Getting Ahead Early

When plant activity is slowed by outside forces like a pandemic, there is little you can do to directly reverse the revenue losses you are experiencing. The more effective option you have is to start looking toward the future.

This is the perfect time to get your facility digitized. Falling revenue may be inevitable in the short term, but you need to secure an advantage for your facility that will help you to make up for that dip later on. Implementing manufacturing control software is an easy and cost-effective choice for this purpose. Once you’ve installed the software, you’ll be in an excellent position to bounce back from this temporary setback once restrictions begin to be lifted and consumer behaviors return to their original state.

You’ll be able to see what level of output the plant is producing on a moment-to-moment basis as well as review other KPIs such as downtime, stock levels, energy consumption, or any other metric which might prove valuable for optimizing your plant. You will also receive immediately actionable insights the program will generate for you based on the incoming data from your workers, machines and environments, synthesizing that information into applicable guidelines that you can put to use right away.

If a work stoppage occurs for any reason, you and your team will be automatically notified of the event and its cause. This allows you to achieve full visibility into your day-to-day operations, giving you the information you need to put your downtime to good use and create a detailed manufacturing efficiency plan for when production ramps up again.

Use it to:

- Scout for weak spots in your production, such as inefficient machine use or poorly coordinated delivery times, that you can correct now to avoid setbacks later on when it really counts.

- Easily collaborate with your team to immediately resolve any issues as soon as they occur.

- Achieve greater overall efficiency in your factory processes, saving you time and money, and potentially allowing your business to expand – all of which makes for a smoother recovery.

You may not be operating at peak capacity right now, but the pandemic and its restrictions will not last forever. When their effects begin to fade, it is digitized factories who will have the best chance of being able to return to their former prosperity as quickly as possible.

Scenario #2: Catching Up to the Surge

For facilities experiencing increased demand, implementing this software provides the chance to realize far more immediate gains, providing an invaluable boost to your productivity at a time when every increase counts. In just a few hours of easy work, you can have your new digital control system up and running, delivering measurable benefits that will quickly begin to have an impact on your bottom line.

When access to the production floor is limited to prevent product contamination, getting real-time visibility and KPIs from the production floor is priceless. Accurate, real-time to the minute data analysis is critical for factory managers trying to optimize production efficiency and take better business decisions.

The best thing is that you can be very agile in your approach. At first, you can begin with monitoring your production analytics and improving collaboration. And as time goes by, you can add more modules to deeply analyze your entire production journey.

To summarize, a robust shop floor control platform can help you:

- Implement fully remote management with 100% visibility in real time. With complete transparency and visibility into production processes remotely for full control over operations managers can view real-time KPIs from any machine, production line or site 24/7.

- Collaborate and share information with other staff members in real time to ensure that work proceeds efficiently despite resource and distance restrictions.

- Keep your entire team communicating with full transparency within the production context, even as people come and go and the scope of work continues to diverge from what everyone is used to.

- Improve manufacturing efficiencies over all areas of production, including staffing, throughput, rejects yield, and more.

You won’t have to wait long to see the impact of digitization; for example, Matics Real-Time Manufacturing Analytics software produces a positive ROI in as little as four weeks, and even that short time frame may be further reduced in such intense conditions. The more efficiently you can meet your production goals while this crisis is still going on, the better you will be able to serve your customers’ needs and the more revenue you will earn as a result.

Digitalizing your production operations is as easy as choosing the right remote manufacturing software to help you do it. With a powerful and multi-functional shop floor control platform like Matics powering your remote manufacturing operations, you will be able to track production from your home, office, or other workspaces even more easily than you could on-site.

Changing the way people work in factories

Request a DemoNow Is the Time to Go Digital at Your Plant

We all know how coronavirus is affecting manufacturers, but that doesn’t mean you have to resign yourself to those consequences. Regardless of whether your factory is booming or languishing right now, you have the opportunity to bring the facility into the digital age and start enjoying the many benefits that real-time manufacturing analytics can bring – and you don’t even have to be on-site to do it.

Contact Matics now to learn how you could install our non-disruptive industry-leading solution from anywhere with just a few hours of your time.