Key Benefits of Smart Manufacturing Software

Smart manufacturing software is one of the pillars of Industry 4.0, providing manufacturers with the means to take control of their operations in entirely new ways. With the right smart manufacturing software solution, your organization can unlock many of these key benefits to accelerate growth and remain competitive in a rapidly changing manufacturing landscape.

Reaching New Heights of Productivity

Increasing productivity on the production floor is one of the key objectives of any smart manufacturing software. Whether through enhanced data collection, advanced analytics, new insights, or better work management tools – the right smart manufacturing platform can bring significant improvements in productivity to manufacturers.

Overall equipment effectiveness (OEE) is the most widely used KPIs to evaluate asset utilization on the shop floor, and smart manufacturing software tackles each of its components:

- Machine Availability: The high-resolution production data and insights accessible through smart manufacturing software let manufacturers optimize the performance of their processes and avoid unwanted downtimes.. Slow cycles, small stops, and other factors that cause performance to drift from ideal cycle times can be identified, understood, and mitigated. The key to this capability is real-time, transparent data.

- Performance: Smart scheduling helps manufacturers make the most of their equipment in terms of availability. Smart manufacturing software allows production personnel to see what needs to be produced and the best way to schedule resources around production.

- Quality: Smart manufacturing software makes it possible to monitor quality performance against specifications in real-time. This lets manufacturers rapidly identify and resolve quality issues, getting processes back under control before large amounts of defective products can accumulate.

Each of these three criteria benefits from the implementation of smart manufacturing software and highlights its impact on shop floor productivity.

Promoting Collaboration Throughout the Organization

Smart manufacturing software isn’t just about machines and sensors. It’s also about communication among the team and streamlining workflows in a more holistic way. Along with providing insight into your processes, smart manufacturing software can also provide communication and collaboration tools to let your team take full advantage of those benefits.

First, smart manufacturing software can consolidate communications into a single platform – preventing important information from being lost. Those communications can also carry context, ensuring that stakeholders investigating a specific process, machine, or event, have immediate access to all relevant information.

Production data and insights are made available to the appropriate individuals throughout the organization rather than being restricted within disparate software packages or spreadsheets. This lets stakeholders in different roles and departments work together more effectively with access to all the information they need. This is often referred to as “data democratization.”

Taking a New Approach to Maintenance

Manufacturing operations must strike a careful balance between planned and unplanned maintenance. Planned maintenance is vital to prevent unexpected stop events, but a schedule with more planned maintenance stops than necessary leads to wasted time, labor, and resources. Smart manufacturing software enables a more robust predictive maintenance approach.

With accurate, real-time production data, manufacturers can better predict when maintenance is required. This lets them shift from planned maintenance based on predetermined schedules to preventative and predictive maintenance that minimizes both planned and unplanned stops.

Maintaining Compliance With Increasing Regulation

Manufacturers face a wide range of regulations related to air and water pollution, material waste, and greenhouse gas emissions. Maintaining compliance with these regulations is a significant undertaking, and regulations continue to become stricter.

Smart manufacturing software plays a key role in maintaining compliance with increasing regulations. First, it allows manufacturers to implement the necessary monitoring and controls to ensure that operations on their production floors align with their policies. Second, the high-resolution production data aggregated by smart manufacturing software lets manufacturers demonstrate compliance with regulatory agencies and other stakeholders.

Making Better Use of Valuable Human Resources

Smart manufacturing software isn’t meant to replace the valuable human resources throughout your organization. Instead, it provides a foundation from which stakeholders in any role can achieve more and make better use of their knowledge, skills, and experience.

Removing repetitive, manual tasks is one way that smart manufacturing software does this. Many manufacturing operations rely on production team members to manually collect data from sensors and gauges and then shuffle that data around multiple software solutions and spreadsheets. Automated data aggregation lets these stakeholders focus on tasks where their skills provide more value, along with eliminating human error in data collection.

Shifting to a Real-time Approach

One of the most notable benefits of smart manufacturing software is the transition to real-time operations. In the past, manufacturing operations have relied on after-the-fact reporting to evaluate KPIs and other important metrics. With smart manufacturing software, stakeholders know what’s happening on the shop floor as it happens.

This allows for an entirely new way to manage operations proactively. Instead of reviewing the past day’s production numbers and making adjustments for the next shift, manufacturers can see productivity and quality issues as they evolve and react immediately. This real-time approach can be the difference between a few defective units causing negligible waste and the loss of tons of material to multiple work orders falling out of spec.

Optimizing Processes Already in Place

New advancements in technology are frequently providing improvements in manufacturing. However, many of those new technologies are entirely different processes that are only suitable for implementation in new facilities or through retrofits that may not be operationally or economically viable. Smart manufacturing software provides benefits for existing manufacturing facilities without the need for significant capital investment or major disruptions to their operations.

Smart manufacturing software provides insights and work management tools that let manufacturers optimize their shop floors. Costs can be reduced by eliminating material and energy waste. New regulatory standards can be met with improved monitoring and control. Smart manufacturing software provides a viable solution for any manufacturing facility, old or new.

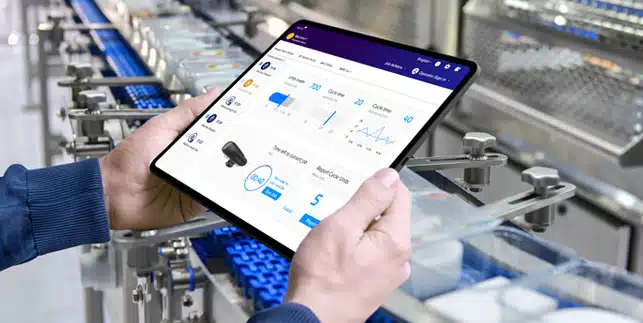

Take Full Advantage of These Benefits With Matics

Matics Real-time Operational Intelligence is a comprehensive smart manufacturing platform that lets your organization take full advantage of these benefits. Real-time production data aggregation and analysis, integrated communications, and advanced work management tools are all easily accessible through customizable dashboards suited to specific roles within your organization.

Discover the benefits of smart manufacturing software for your operation by reaching out to Matics for a demo of Real-time Operational Intelligence today.