The Impact of Industry 4.0 on Food and Beverage Manufacturing

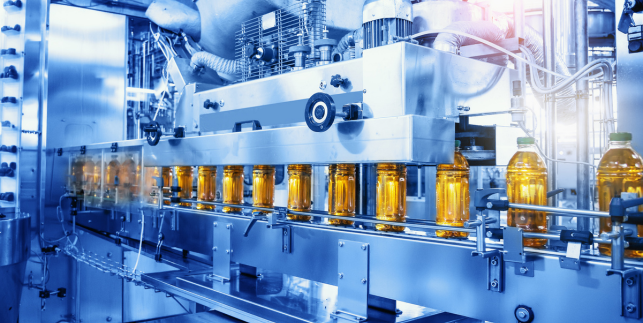

Manufacturers around the world are adopting Industry 4.0 technologies at a rapid pace to face modern challenges and prepare for the future. The food and beverage sector is no exception, with operations implementing a variety of new technologies and solutions to improve productivity, reduce waste, and achieve sustainable manufacturing.

The impact of Industry 4.0 and smart manufacturing on food and beverage manufacturing is already visible today and will only continue to advance as adoption increases and new technologies and solutions emerge.

Achieving Supply Chain and Operational Traceability

In food and beverage manufacturing, traceability is one of the most important areas that manufacturers must address. Alongside meeting fundamental logistical and operational requirements, they must also ensure compliance with a wide range of health, safety, and sustainability requirements.

The data collection and management required to achieve that level of traceability presents a significant challenge, one that Industry 4.0 technologies provide a solution for. Automated data collection removes human error and reduces labor requirements in the comprehensive cataloging of all production data for individual batches and production runs.

Many Industry 4.0 solutions involve the use of a central platform with connectivity and compatibility to consolidate production data from all sources and maintain important context. This streamlines traceability considerably, eliminating the need to seek out data across different systems and platforms.

The implantation of new technologies also serves to improve traceability. Various IoT sensors and devices automate monitoring and tracking throughout supply chains and on the shop floor. Combined with a central platform that manages all data, this lets manufacturers maintain traceability over specific product lots in case of inspection requirements or recall.

Reducing Waste to an Absolute Minimum

Eliminating waste is a central component of sustainability efforts across all industries. In food and beverage manufacturing, material waste is a major concern in terms of both sustainability and profitability.

Giveaway is an ongoing challenge that most food and beverage manufacturers must contend with. Fill variation in packaging and bottling results in individual units varying slightly in their weight or volume. Manufacturers must maintain tight thresholds to ensure an accurate fill. Insufficient fill risks consumer complaints and even regulatory penalties. Excess fill results in giveaway, increasing production costs.

A variety of automated weighing and filling technologies allow manufacturers to achieve tight tolerances. However, there is still the challenge of communicating issues to production teams and technicians and enacting a rapid response to mitigate losses as quickly as possible.

Industry 4.0 provides improved connectivity for weighing and filling equipment, providing information in real-time to the central platform. From there, KPIs and thresholds can be monitored automatically, and the platform can provide alerts and even automated workflows in reaction to any fill variation issues.

Improving Quality Control Methods

Quality control is essential in any food and beverage manufacturing context. Maintaining health and safety is paramount, and manufacturers must also ensure that quality meets consumer expectations. Industry 4.0 provides a variety of solutions for more accurate and effective quality control.

New sensor technologies are emerging to provide greater accuracy in quality control. These include a variety of sensors not conventionally used in manufacturing contexts, such as image-based detection. These technologies broaden the scope of quality defects that can be detected automatically and are well suited to food and beverage manufacturing, where visual quality is of the highest importance.

It’s not just the underlying technology of these sensors that delivers manufacturing benefits but also their synergy with other elements of Industry 4.0. Many such sensors are IoT devices that provide seamless connectivity, making them easy to integrate within existing processes without additional infrastructure.

The additional production data created by these sensors can also be aggregated and analyzed by a central platform. This can greatly reduce latency between events and responses while also introducing new opportunities to better understand and optimize production processes.

Optimizing Production With Digital Twins

Digital twins are among the most powerful Industry 4.0 tools for understanding and optimizing production. Many manufacturers already enjoy the benefits of digital twins today, using them to model their production processes and achieve improved monitoring, scheduling, and optimization.

A digital twin is a virtual counterpart to a specific machine or piece of equipment within your facility. It brings together all real-time and historical production data concerning that machine into one place, allowing for a complete understanding of performance and any potential issues.

Within a central platform, the insight provided by digital twins lets manufacturers better plan production. Using historical production data from the digital twins, the platform develops accurate forecasts of the impact that changes in workflow, scheduling, and other parameters will have on production.

Digital twins let manufacturers understand the potential impact of their decisions and offer a common frame of reference for collaboration among stakeholders. Operators, technicians, and other parties have accurate access to all data concerning specific machines, along with consolidating communications about issues and events related to that machine to provide context and avoid any information loss.

New Methods for Predictive Maintenance

Maintenance is an integral part of any manufacturing operation. Manufacturers can schedule their planned maintenance requirements to minimize downtime, but they still face the impact of unplanned maintenance. Industry 4.0 provides tools that reduce that impact through predictive maintenance.

Predictive maintenance is the practice of determining when equipment requires service or replacement parts to avoid failure or unplanned stop events. In food and beverage manufacturing, particularly in packaging, many machines feature components such as molds and dies that require regular maintenance to prevent quality decline.

Scheduling that maintenance too often means more downtime, but putting it off for too long risks unplanned stops. Industry 4.0 solutions implement advanced analytics based on quality and other production data to determine how soon maintenance is required. This predictive insight lets manufacturers improve planned maintenance scheduling without risking unplanned stops.

Dealing With Product Complexity

Many food and beverage manufacturers produce a wide range of different products using the same production lines, even implementing short-run work orders or other custom work. This can increase complexity in production and introduces the risk of errors and inefficiency.

Industry 4.0 solutions confront this problem in several ways. They provide improved interfaces between systems and production team members. Scheduling and work orders are more clearly communicated through a central platform that maintains consistency. Instructions regarding material selection, machine configurations, and setup are communicated automatically to avoid errors.

The use of historical data in dynamic scheduling eliminates inefficiency when dealing with varied work orders. The central platform provides clear and accurate forecasts for overall job time and specific machine use for individual work orders, facilitating scheduling even in complex operations.

Real-time Visibility Over Production

In food and beverage manufacturing, reacting quickly to defects can significantly reduce losses. When processes are out of control or quality criteria thresholds aren’t being met, waiting until scheduled inspections or discovering the problem after the fact wastes both raw materials and production time.

One of the key aspects of Industry 4.0 is the transition to real-time production data. Instead of collecting and compiling data after production, information is continuously gathered and analyzed. Increased connectivity with machines of all kinds makes real-time collection possible, and the powerful analytics provided by a central platform generates insights from that data in real time.

This greatly improves visibility over production, allowing manufacturers to monitor the state of all machines and equipment in real time. Continuous monitoring of KPIs and other criteria lets production teams understand where they’re at and where their efforts should be focused throughout their shift.

Meeting Modern Sustainability Standards

Food and beverage manufacturing faces stringent standards when it comes to sustainability. There is a significant push to reduce waste overall, and many specific regulations and requirements concerning packaging. Industry 4.0 solutions make it possible to meet sustainability standards in food and beverage manufacturing.

Many sustainability standards call for the use of different raw materials and ingredients in both food and packaging manufacturing. Any change in formulation or recipe introduces the risk of quality issues, so manufacturers need new tools to capture and understand production data. A central platform can bring all of that information together to understand the impact of changes and plan accordingly.

Demonstrating compliance with new regulations is also vital. Real-time production monitoring captures all material consumption data, allowing manufacturers to verify recycled material content and other information. Monitoring consumption in real-time also enables manufacturers to ensure that planned changes are implemented accurately within production lines.

Realize the Benefits of Industry 4.0 With Matics

These are just some of the areas where Industry 4.0 solutions have already made an impact on food and beverage manufacturing, with even greater benefits on the horizon. Manufacturers must find the right solution to realize those benefits, a solution that offers the tools they need and an implementation that synergizes with their existing resources.

Matics Real-time Operational Intelligence (RtOI) already fulfills that role for many food and beverage manufacturers around the world. Real-time visibility, powerful analytics, and a range of tools to improve productivity, sustainability, and traceability allow manufacturers to face modern challenges. Schedule a demo with our team to discover the unique benefits that Matics RtOI can bring to your operations.