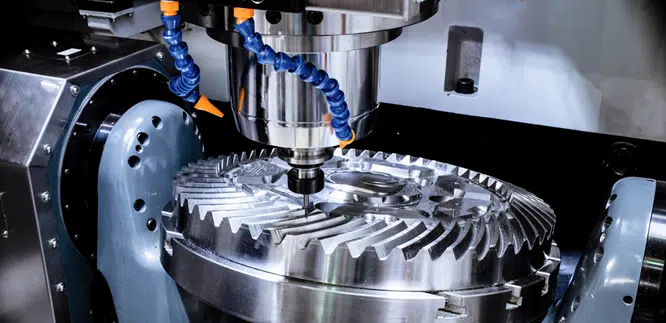

CNC Machine Monitoring Software: What Is It and How to Improve Efficiency?

Increasing automation has made CNC machining a highly productive and profitable business, driving a projected annual growth rate of 5.5% between 2019 and 2026. Medical and aerospace industries are amongst the biggest users of CNC machinery, as well as defense and petrochemical companies, in which precision is an absolute must-have.

However, greater operational efficiency is always possible and should be a top goal of any CNC machining business. CNC machine production monitoring has the potential to significantly boost efficiency inside facilities on both machine-by-machine and a holistic basis. Shop floor control software is a simple solution that you can use to oversee CNC production processes and identify any complicating factors that are hindering your factory’s potential.

Downtime and CNC Productivity

Almost all CNC productivity problems first manifest as problems with machine availability, one of the key factors in your OEE. The high level of automation present in this process ensures that machines are always functioning extremely efficiently when they are operating. However, every second during which they are available but not in use represents wasted potential.

Getting an idle machine back to work as soon as possible ensures that its productive capacity does get put to use. The reasons why the machines in question are experiencing so much downtime will vary (a lack of materials or faulty machines), but all of them can be addressed once you know a problem exists. In many instances it will be the waiting time, when a single operator is attending to multiple machines in turns. In other cases, time is needed for QC purposes – to inspect a part for assuring its accurate measurements with precision.

Determining when and why a CNC machine in your facility is idle is the first and most important step to reducing downtime and improving overall production efficiency.

Establishing Clear Data for Better Analysis

CNC machine monitoring software performs extremely well on its own, although some human input is occasionally required. These systems are designed to be simple and accessible for workers at all times, breaking down the usual barriers that impede accurate data collection.

For example, CNC requires more human intervention than most production methods. This means that they will often experience work stoppages that are not necessarily planned or scheduled but are unavoidable and not a cause for concern. You can measure the manual work invested during each production cycle and set a standard KPI over time, which also comes in handy with cost analysis.

Shop floor control software alone cannot distinguish between this type of downtime and the type that does pose problems. However, it does allow users to input information about the reasons why production stopped in each case of a work stoppage.

This can be done when the stoppage occurs or at any point afterward; if a worker cannot spare a moment to update the records at the time of the crisis, they can always add their notes later on when they are free to do so. This flexibility should make it possible for your factory to keep accurate, up-to-date records that distinguish necessary interruptions from harmful downtime.

Features like this allow you to better measure the actual gap between real-time production efficiency and the efficiency level you know you should be able to achieve. Whatever gaps still remain after you have accounted for production wrinkles like this represent true problems inside your facility that you can then investigate and correct.

Improve Production Efficiency And Transparency With CNC Machine Monitoring

Using a CNC production monitoring system allows you to maintain constant supervision over your CNC production machines. Without an advanced factory floor solution, production visibility is limited to manual observation, and it’s simply impossible to manage multi-stage production processes in a holistic manner and achieve full transparency on your factory floor.

A smart shop floor control software connects digitally to all of your equipment and collects data on metrics such as how many pieces are being produced per hour, relative to the standard cycle time, how those pieces measured up to your quality standards, when and why work stoppages occurred, and much more. It not only tracks and records this data, but it can also send automatic alerts to notify you and your workers about any discrepancies it finds.

Powerful Factory-Wide Optimization

In addition to its immediate benefits, CNC machine monitoring software also allows you to leverage your factory’s production data to make continuous improvements to your production processes. The software contains many tools to break down and analyze this data to bring you useful insights to apply within your facility.

Essentially, without effective CNC production monitoring, you might never uncover certain problems. However, once you know about them, you can investigate the root cause and resolve it, recapturing that formerly lost productivity on all subsequent CNC production rounds. In this case, you’d be able to avoid much more serious consequences later on by catching a burgeoning problem early.

Not only does shop floor software provide the information needed for various discoveries, but it also makes it easy to understand. It uses bold, simple visuals that you and your workers can use to quickly get the information you need and take action when necessary.

The software can also suggest further actions you can take to improve production efficiency based on what it has observed over time, taking some of the guesswork out of the optimization process. For instance, it can send automatic notifications and calls-to-action to the operator when it’s time for machine maintenance procedures.

Changing the way people work in factories

Request a DemoCNC Machine Monitoring Made Easy

CNC production monitoring is easy to do and has clear benefits for facilities that implement it. From immediate corrections to long-term adjustments, it has the potential to significantly increase your factory’s output and revenue. Investing in shop floor monitoring software that can collect, archive, display, and analyze CNC production data largely on its own is a proactive decision that will undoubtedly improve production efficiency on the floor.

Matics provides industry-leading shop floor control software that is often used for CNC machine monitoring purposes by customers. Our solution includes all of the features described above and more, and its plug-and-play setup and cloud-based structure make it easy to use and install with minimal technical help. Contact us at any time to learn more about our proven software solution and how it can help you keep a closer eye on your CNC machines and their productivity.