Smart KPI’s in Manufacturing

How Setting Effective Targets with KPI Management Lets Manufacturing Operations Continually Improve

Key performance indicators (KPIs) are an essential part of tracking production in manufacturing. But they aren’t just for evaluating past performance: they play an integral role in the ongoing improvement of any process. How an organization handles KPI management will have a significant impact on how effectively they lead to real progress.

Anyone can collect data. Determining the appropriate context and translating that into actionable outcomes is the tricky part. The change towards more effective use of KPIs isn’t just a matter of collecting more data and committing more resources to review that data. It’s part of a larger organizational change that shifts management into a more proactive and data-driven production framework.

Taking a SMART Approach to Manufacturing KPIs

Among the most significant manufacturing KPIs within any production environment is overall equipment effectiveness (OEE). Availability, performance, and quality all play into OEE, which translates quite directly to productivity on the factory floor. Therefore, organizations looking to get the most out of their KPI management should focus on making their OEE goals SMART, that is:

- Specific

- Measurable

- Attainable

- Relevant

- Time-bound

Specificity is the hallmark of any effective target. Managers cannot simply say that their OEE should be “better.” The results they’re looking for must be tangible. That means there needs to be an actual number attached to any goal, whether that’s equipment availability, yield, or other factors. This also means that goals should be clear about which processes, machines, and individuals are involved, affected, and responsible.

To be truly effective, the goals must also be measurable. Even if a target is specific, if production doesn’t have the means to measure it accurately and reliably, it won’t be evident if the target has been met. Managers must carefully consider how these measurements are being taken and how they relate to the target. Is the target metric being actively monitored, is it averaged across shifts, can they act on the information they’re gathering?

When some metric has been selected to serve as the target, there is still the question of what the specific target value is going to be. For effective improvement, managers need to choose goals that are actually within reach of production. A plan that is put into place within a production environment should have tangible steps that can be taken to move towards it. How can the target be met, and who is going to implement those steps?

Choosing suitable OEE targets also means selecting KPIs that are relevant to the continued success and improvement of the production operation. Managers must consider whether or not the target is beneficial to production’s bottom line and to what extent. Devoting significant time and resources to working towards irrelevant goals would be a tremendous waste and a substantial source of organizational inefficiency.

Finally, targets must be time-bound. There should be a specific timeframe for any goals that can be used to gauge the success or failure of improvement efforts. Having a running target without a clear endpoint isn’t beneficial because none of the parties involved will be able to gauge how much or how little progress is being made compared to the intended outcomes.

KPI Targets as an Ongoing Process

Of course, setting and achieving SMART goals is far from the only essential factor in KPI management. Organizations also have to realize that defining, setting, and fulfilling or failing goals is an ongoing process. There must always be new goals to implement moving forward, drawing on the experience and learning of previous targets to better fulfill the tenets of a SMART goal.

In some cases, this could mean a major shift in focus. When goals for quality assurance KPIs in manufacturing aren’t met or fail to produce the desired outcome when met, a revaluation is in order. Managers will have to go over the SMART principles in order to find out exactly what went wrong with their planning. Perhaps they lacked some crucial context around the KPIs they’ve been managing.

When goals are successful, this leads to an opportunity for continual improvement. Plans can be adjusted for even greater OEE, constantly pushing processes to improve in new ways. During this process, managers have the opportunity to investigate how different elements of the production come into play and influence specific KPIs, potentially spurring innovation in developing new solutions.

It’s also important to contextualize targets within the greater production framework. The criteria, strategies, and principles that go into individual targets aren’t isolated but are all part of the bigger picture. Ensuring that targets are worked towards without compromising other production elements is essential for long-term success and a major challenge in KPI management.

Building an Effective KPI Management Strategy

Developing an effective strategy is essential for improving production KPIs. One of the primary questions when it comes to that is whether the organization is going to set targets from the top-down or the bottom-up. Both strategies have unique benefits and challenges.

Setting targets from the top-down means setting an overall goal for the entire manufacturing operation. A manager might decide that improving cycle time efficiency some certain amount is the target. From here, they have the work of determining where they can make changes to achieve this target. Are there specific machines and process steps that aren’t meeting their potential, which departments are responsible?

Targets from the bottom-up entail setting targets for individual machines and process steps. This provides apparent and direct goals for production, but it isn’t always clear how these goals are going to affect the organization as a whole. Both strategies can be effective in different situations.

Changing the way people work in factories

Request a DemoTaking Control of KPI Management With Matics

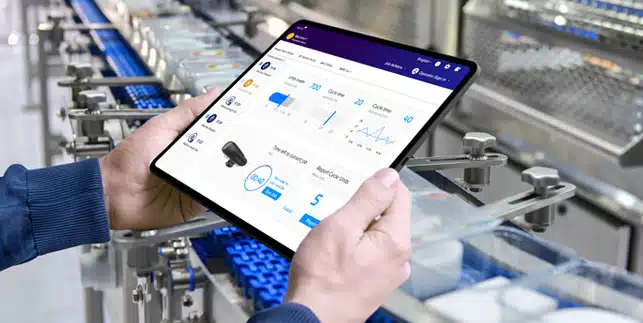

Matics provides a solution that makes KPI management attainable and effective for production operations. The manufacturing dashboard increases team engagement by making the ongoing tracking and progress of KPIs accessible to all workers. The unique presentation of manufacturing performance indicators within a single dashboard lets everyone understand where a process stands and how progress is being made.

This also includes past data that serves as an essential tool for setting benchmarks and future goals, with integrated tools for adjusting those benchmarks and categorizing performance for streamlined communication. Managers can evaluate KPIs overtime at a variety of different levels of analysis. They can be broken down by individual workers and machines to give the highest resolution overview of trends that serve to facilitate more effective target setting.

The platform makes adjusting key performance metrics for manufacturing much easier by allowing them to be accessed through a single dashboard. Managers can change and scale KPI targets across the organization simultaneously or lock specific KPIs that they don’t intend to change at that time. It allows for both top-down and bottom-up goal-setting for manufacturing performance metrics.

The dashboard allows for versatile monitoring and evaluation of current and past KPIs. Poor OEE can be detected in real-time and addressed immediately. The platform makes it easy to identify specific shifts and machines that are underperforming, providing actionable data for improving manufacturing KPIs.

Matics could have the solution for your organization’s ongoing need for KPI management. Our versatile platform will empower workers at all levels of the organization to make meaningful steps towards improving production KPIs both in the short and long term.

Contact our team today to book a demo and see how Matics can help you.