Why Your Factory Needs Shop Floor Control Software

Maximizing production is the ultimate goal of any manufacturer. Manufacturing shop floor control software can help you to achieve that goal. By shedding light on the specifics of how your company is operating, this tool will allow you to gain greater efficiency by optimizing your machine use, inventory, staffing, and other variables.

What Is Shop Floor Control Software?

Manufacturing shop floor control software – or manufacturing execution system (MES) software – allows you to collect, access and analyze relevant data from your factory’s operations. It collects data from human and digital sources alike on an ongoing basis as work progresses.

With this software in place, you’ll be able to keep track of everything that is going on in your factory in real time. You can pull detailed reports that will tell you how long the machines have been running, how much material has been used, how much of the day’s work is left to be done, and other important numbers and statistics.

Further, the data this software can provide is not limited to an overview of a single department or factory. It can gather relevant information for many different manufacturing facilities at once as well as for individual machines in a single facility. This allows you to track KPIs from as many input points as possible, giving you a clearer picture of all of the factors influencing your company’s total output.

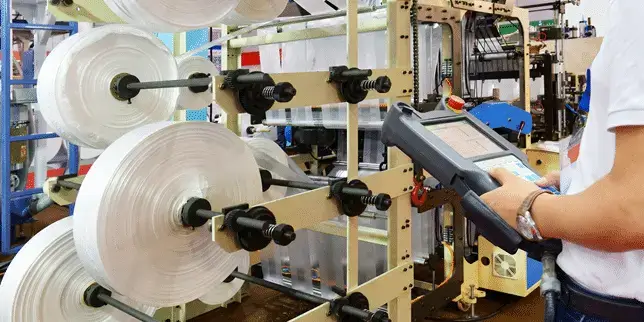

Depending on the permissions you set, shop floor control systems can be used by managers, supervisors, workers, executives, administration professionals and anyone else involved in the factory’s operations. They are also suitable for any industry, including but not limited to:

● Plastics and rubber.

● Automotive.

● Metal.

● Textiles.

● Food and beverages.

● Cosmetics.

● Paper and printing.

The Difference Data Makes

The information and digital infrastructure that shop floor software provides can bring significant value to any manufacturing business.

As mentioned above, this software is constantly collecting data on every aspect of your facility’s operations. With full sets of data encompassing multiple days, shifts and locations, management can pinpoint the areas where performance falters and address the shortcomings that are leading to that outcome. They can also intervene when indications suggest that a problem (such as a shortfall of materials or a piece of equipment that is producing product that falls below quality standards) is developing. This process is aided by the alert system built into the software which will notify users when a useful insight has been automatically gleaned from the stored data. Every adjustment you make in response to these notices could dramatically improve your facility’s efficiency.

Because it can potentially be seen by even the most low-level worker, however, that data can also serve as a motivational tool to bolster your weaker workers. Those individuals can see the data produced by their own machine and know that they are objectively underperforming. They can then attempt to correct that issue and observe whether or not their solution achieves the desired results. This allows each team member to be accountable for their own efficiency with clear benchmarks to help them develop.

Using MES software solutions also makes it possible for you to switch over to all-digital information management. Unlike physical paperwork which takes up space and can easily be damaged or lost over time, digital data can be easily stored for decades to come at minimal cost. You will never lose access to your valuable historical data and you will have a far easier time pulling useful information from your records as well.

Why Matics Is the Right Brand to Help

There are countless different brands of shop floor software out there, but manufacturers who want as much functionality as possible understand that it pays to be picky about which you choose.

Unlike previous generations of manufacturing control software, which could only collect data after a period of delay, Matics’ leading shop floor control software includes advanced real-time capabilities that deliver up-to-the-minute data on your factory floor. You can use our shop floor control system to gain full visibility into your operations and implement tangible improvements to your production processes.

Matics is easy to install and deploy in any environment, no matter what machinery or systems you are currently using; most factories can have it running mere hours. With its user-friendly interface and automated analytics tools, it won’t take long for your staff to adapt to using it in their day-to-day routines. You should start seeing results in as little as a few weeks.

Further, Matics’ software solution is a cloud-based MES. This means that you, your workers and your colleagues can all access the software at any time and from any place. Whether you’re checking up on how work is proceeding just before bed or responding to an urgent matter while on vacation, you’ll always be able to tap into the system and evaluate the situation. Time and distance will no longer be a factor in your ability to manage your facility’s efficiency.

You can also use this cloud-based functionality to easily collaborate with other team members across multiple departments or hierarchical ranks, sharing the same data as you work to achieve common goals. This ensures that everyone is basing their decisions and conclusions on the same information, eliminating confusion that could result in costly mistakes.

All told, Matics’ impact has been responsible for production increases of up to 25% in many manufacturing facilities.

Changing the way people work in factories

Request a DemoBring Out Your Factory’s Full Potential

Information is power, and shop floor control software is any manufacturer’s key to acquiring more of it. Without this valuable tool at your disposal, your factory will struggle to reach full production capacity. With it, however, you may be able to achieve results you never thought possible.