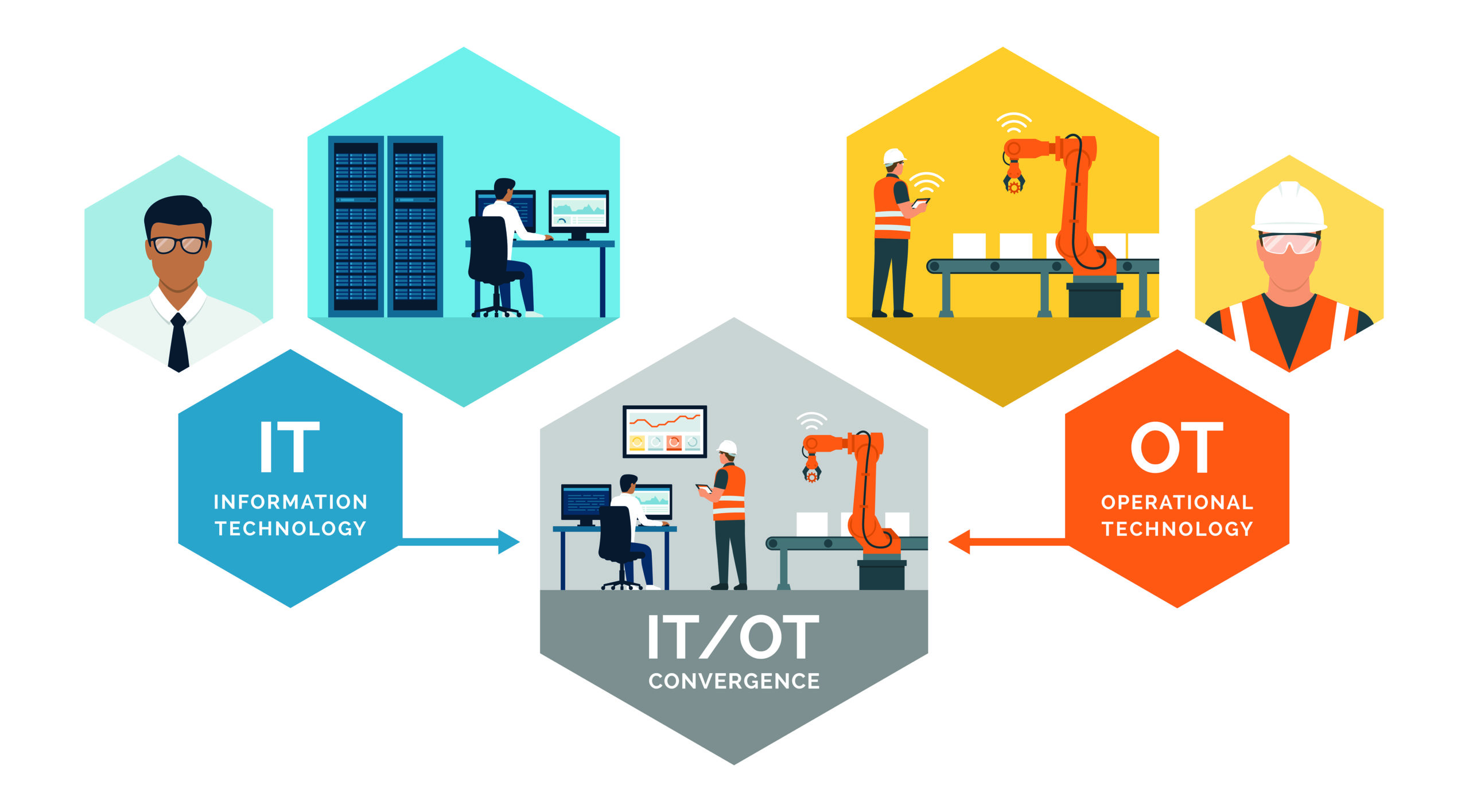

One of the ongoing developments in Industry 4.0 today is IT/OT convergence. Manufacturers rely on both IT (Information Technology) and OT (Operational Technology) systems to operate their manufacturing plants effectively.

Traditionally, IT/OT systems have been separate and distinct, but new solutions are bringing them closer together than ever before. Real-time Operational Intelligence lets manufacturers take full advantage of the synergy of IT/OT convergence thanks to real-time data analysis, work management tools, automation capabilities, and more.

OT and IT Systems in Manufacturing

In conventional manufacturing, there has always been a disconnect between OT and IT systems. While both are vital sources of information to any manufacturer’s success, a lack of true synergy between the two systems prevents effective collaboration, improvements in efficiency, and leaves manufacturers unable to realize the full potential of either.

On one side, manufacturers have OT systems that play a direct role in production; These are the systems that monitor processes and events, giving production teams a view of what’s happening on the factory floor and allowing for control and adjustments.

On the other side, IT systems focus on data and business intelligence – They allow for coordination of sales and inventory, data analysis, and communications. IT systems include both internal and external communication but remain separate from OT systems.

Because OT systems aren’t connected to each other or to other systems, they rely heavily on operators to serve as intermediaries between processes, devices, and systems. As a result, manufacturers require more operators to monitor and control OT systems that aren’t capable of networking or control automation. Not only is this more expensive, but it introduces opportunities for human error.

Individual OT systems often create information silos that prevent the free flow of production data. When IT systems require access to this data, they must once again rely on operators to serve as the link between the two systems.

However, modern developments in IT/OT convergence are making it possible for these two systems to work together more effectively.

IT/OT Convergence

Industry 4.0 has brought a variety of advancements that are making IT/OT convergence a reality for manufacturers. The Industrial Internet of Things (IIoT) provides realistic methods for existing OT systems to become more networked and achieve higher connectivity. Advances in IIoT devices and connectivity are being accompanied by similar advances in software to bring it all together.

By establishing meaningful links between the two separate systems, IT/OT convergence opens the door to an entirely new approach to manufacturing. The potential for analysis, collaboration, control, automation, and more are all increasing dramatically.

The Benefits of IT/OT Convergence in Manufacturing

The most immediate benefit to manufacturers is the shift toward networking between the two systems. Now, data from either system can be readily available to the other. Manufacturers will no longer rely on operators manually transferring data between the two, reducing labor requirements and improving the accuracy of production data.

With production data straight from the source, IT systems can more accurately track production and inventory, providing important information for management, sales, quality control, and other departments.

Access to a wider range of accurate production data also introduces more opportunities to optimize processes. Now, manufacturers can analyze material and energy use more effectively, allowing them to improve usage efficiency over time.

Increased visibility across both systems allows for improved collaboration across manufacturing operations. Stakeholders at different levels and in different departments will have greater access to a wide range of data, eliminating the barrier between OT and IT systems.

Information also flows from the IT systems to the OT systems. A direct link allows for changes in inventory and work orders to translate to changes in production scheduling faster and more accurately. This creates a more agile manufacturing environment and further reduces waste.

The Challenges of Implementing IT/OT Convergence

IT/OT convergence is an important step towards Industry 4.0 for manufacturers. However, realizing the benefits of IT/OT convergence can be a challenging transition. There are many considerations that manufacturers will have to take into account before, during, and after the transition.

Many of the potential problems that can arise during IT/OT convergence are due to legacy OT systems. These systems are often highly specialized and were not developed with the expectation of future networking with other systems.

Establishing a link between these systems is rarely a simple process. While IIoT devices provide effective tools in many cases, manufacturers still require an overarching solution to bring together OT and IT systems.

Security is often a major concern during IT/OT convergence implementation. Due to the lack of original networking, most OT systems aren’t particularly compatible with modern security requirements. Manufacturers can’t assume anything about their security posture and will need to ensure that their overall solution takes security into account.

IT/OT convergence isn’t restricted to installing new IIoT devices and software solutions. There is also the importance of employees and workflows. Adapting workflows to take advantage of IT/OT convergence can be difficult, and manufacturers can find themselves dealing with resistance to the implementation.

These challenges mean that manufacturers can’t implement IT/OT convergence on their own. Instead, they need a solution, guidance, and support from developers who specialize in this kind of Industry 4.0 manufacturing transformation.

Real-time Operational Intelligence

Real-time Operational Intelligence (RtOI) solutions are redefining the manufacturing space, making it possible for manufacturers to realize the benefits of IT/OT convergence and overcome the challenges to its implementation.

RtOI solutions aggregate and analyze production data from all systems in real-time, providing a single-source-of-truth for data, vital to achieving IT/OT convergence. This enhances visibility, collaboration, communication, optimization, and more.

Real-time Operational Intelligence solutions make data accessible and intuitive while simultaneously serving as an integral part of shop floor workflows with the implementation of automation, alerts, and more. Having such a versatile work management tool that leverages connectivity with both OT and IT systems enables manufacturers to overcome IT/OT convergence challenges while having a tangible impact on important KPIs and metrics.

Ultimately, the place RtOI fits in terms of IT/OT convergence is in its ability to transform their factory floor by connecting processes, data and physical devices.

Process Convergence

Process convergence is among the most challenging elements of IT/OT convergence. It’s the task of bringing together workflows across various systems and departments into a cohesive approach that takes advantage of greater access to data, communication, and collaboration.

RtOI makes this possible through the use of real-time work management tools. Manufacturers are able to create automated workflows that rely on data and analysis from a wide range of systems. These allow for new workflows that take advantage of the real-time monitoring and alerts that are now possible.

Data Convergence

OT and IT systems both create valuable data. The data from these two sources can be used together to generate new insights and continuously improve operations. However, the disconnect between systems and the potential incompatibility of software and data formats makes achieving those benefits challenging.

RtOI can aggregate and analyze data from a wide range of sources, including machines, IIoT devices, and existing OT and IT solutions. With RtOI, this data is available in real-time and can be used in decision-making and analyses. RtOI implementation makes it possible to bring disparate systems together through a single platform.

Physical Convergence

RtOI plays an essential role in physical convergence as well. Physical convergence involves the replacement or retrofitting of older OT systems to make them compatible with other systems and enable the necessary connectivity and networking.

Because RtOI can aggregate data and communicate with such a wide range of existing systems, it can reduce the requirement for new physical equipment during physical convergence. This reduces the overall cost of IT/OT convergence for manufacturers.

Changing the way people work in factories

Request a DemoHow Matics RtOI Faces the Key Challenges of Implementing IT/OT Convergence

Matics is a Real-time Operational Intelligence (RtOI) solution designed to digitalize manufacturing shop-floors with ease by providing a real-time work management tool that analyzes data in real-time and delivers the right information at the right time to the right people.

The Matics RtOI solutions can bring together OT and IT systems and provide advanced analyses and workflow management tools to obtain the highest possible benefits from the synergy between those systems.

Matics RtOI is a secure, cloud-based solution that provides additional remote access and communication capabilities. The robust security features implemented within the solution address the potential security concerns of implementing networking and connectivity in OT systems.

Matics RtOI can be accessed through a variety of different dashboards with customization options. This enables manufacturers to cater access to the solution to different roles within the organization. Intuitive and clear dashboards allow for employees to adapt more quickly and generally improve adoption.

Matics provides ongoing support throughout the transition. The modular design of Matics RtOI allows for integration with minimal impact on operations. Manufacturers can achieve IT/OT convergence without significant downtime or difficulty.

Matics RtOI also sets a foundation to realize additional benefits of Industry 4.0. The versatile solution can accommodate future OT and IT systems and is continuously evolving to provide new features and increased functionality.

If you would like to hear more about how RtOI can help your manufacturing operations achieve IT/OT convergence and unlock its benefits, you can contact Matics today to schedule a demo with our team.