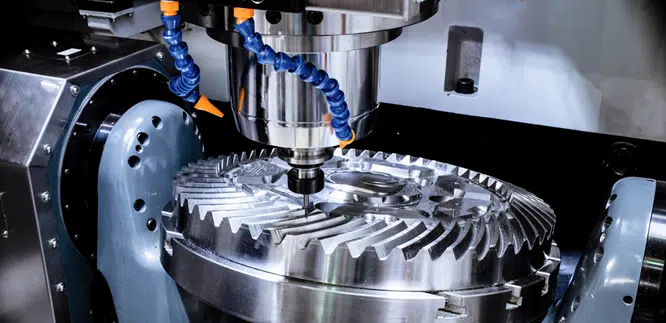

How Matics Helps Maintain Factory Efficiency in a Crisis through Remote Management

The need to rethink crisis management and streamline remote-work for all industries was rapidly accelerated due to the 2020 global Covid crisis. Today, as the global community learns to deal with the changes the pandemic necessitated, many manufacturing plants have realized that going back to pre-Covid times is not an option. As a result, the ability to access production floor

Last Modified: December 27, 2023