Magic Adopts Real-time Manufacturing Analytics for Optimized Decision Making

How did Magic Polo Plast, a plastics manufacturer, improve production and save money with Matics?

By Eran Appel, Magic CEO

Our Goals: Eyes on the manufacturing floor 24/7

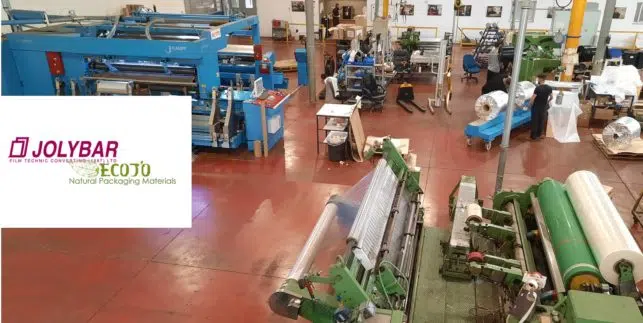

Magic Polo Plast is a plastics manufacturing plant that was established in Kibbutz Ma’anit in Israel over 20 years ago. It operates 12 production lines and injection machines and has about 30 employees at its service.

When I first arrived here, my goal was to stabilize the entire production floor, and to start organizing procedures in order to turn this small family operation into a much larger business with increased capabilities and infrastructure that would allow it to grow.

It was very important for me to be able to see and to understand what was happening on the production floor without having to be physically present there at all times. The factory is running at night while we are sleeping. When we would arrive the next morning, we wouldn’t know if all the machines worked or not unless we would go down to the production floor to evaluate how many products had been produced during the night.

Implementing Matics: Easy, Fast, with Very Few Adaptations

The initial implementation process with Matics was seamless and effortless, not to mention very quick. It took about two-four weeks for Matics to connect all the machines to the controllers, and then an additional two weeks to complete the system set up and ensure everything was running smoothly.

One of the greatest things about this system is that the software at its core is delivered with all the options that we wanted and were looking for, so there was no need for long programming and major changes. As far as we’re concerned, it’s an off-the-shelf software.

The Challenges: Turning a Fear of “Big Brother” Into a Positive Competition

Our main challenge was to make sure that the people, the employees had all the tools to operate the system adequately and to simplify the working process as much as we could for a smooth run.

On the second day that we implemented the system, we noticed that the cycle time in one of the machines had increased by a few seconds. After doing some research it turned out that at night the production cycle time was automatically extended.

This phenomenon was the norm within the factory for years. It is also common for workers to slow down with the hours and as a result, decrease their working speed during the night shift. But, the employees at Magic didn’t know how much their work affected the overall result of the factory production.

When the workers realized that we can see them and that we can tell exactly at which point in time the production cycle changed – ultimately, they understood that it was the livelihood of each one of us that was actually at stake.

Shortly following Matics’ implementation, a positive spirit emerged from the Magic’s team. Employees were now more motivated and dedicated to each shift. This positive environment fosters positive outputs which only keeps on improving.

We’ve connected all the shift managers and all the maintenance managers to the Matics application. This provides the employees with a sense of belonging and responsibility, and they feel that they are part of this team that drives this business to success.

The Benefits to Magic: Data-based Decision Making in Real-time, Greater Efficiency, Money Saving

One of the greatest benefits Magic gained from utilizing Matics is the ability to see what is going on in the factory, in real-time, and make data-based decisions on the spot.

In the past, we’ve had to finish an entire series of products to find out if the machines were working properly or not, but today our access to data is online and immediate.

Magic no longer holds any meetings without the Matics system. Each operations meeting consists of reviewing the factory’s data through Matics. This gives the team a clear view on machine’s statuses, delays, stops, and more, enabling them to conduct an accurate diagnosis of the factory at all times.

Today, we analyze the production floor on a daily basis. This means that every day we receive a report that lists where we should have been according to standards; where we stand in relation to our goals. And if we run into a problem, we are aware of it on the spot, and we can alert the team to check and make the necessary repairs.

Over the past years, we were able to make decisions regarding certain products – some were put on hold because they proved to be less effective in connecting the product, the mold and the machine. We also found that investing in a new mold in a certain product has improved efficiency in the product.

Matics provided Magic with the ability to successfully analyze data more accurately. The more accurate the data, the more accurate the solutions. Magic no longer base decisions on gut feelings – but on real-time data.

This ability to drill down and to understand what has happened, how and why, continuously helps us reach efficiency and save money.